CCS

Evaluation of Potential Reservoir for Carbon Dioxide Capture and Storage

Carbon dioxide capture and storage (CCS) technology injects CO2 emitted from the combustion of fossil fuels into the ground, thereby contributing to curbing global warming.

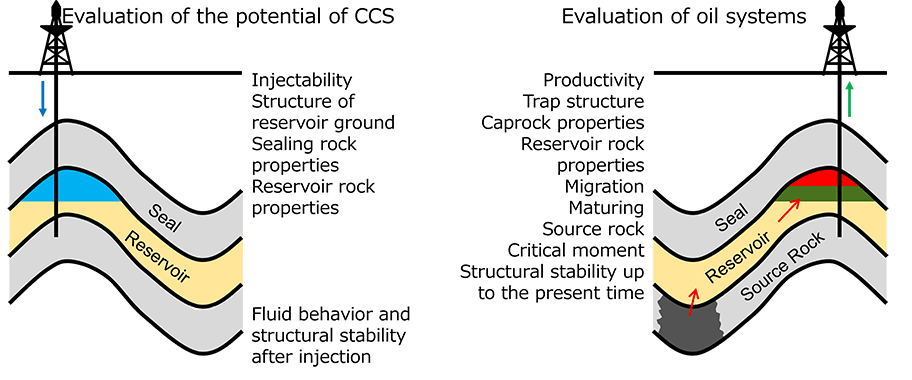

For the effective storage of CO2 underground, a suitable distribution of both permeable and impermeable rocks is necessary. One such example is a combination of sandstone that enables the injection of CO2 and mudstone that seals the injected CO2 and prevents leakage to the surface.

Overall, this combination of sandstone and mudstone is crucial for the formation of certain oil and gas fields. Therefore, expertise in geology and geophysics, which is necessary for exploring hydrocarbons, is also used to choose suitable sites for CO2 injection.

INPEX has conducted exercises to select CCS sites both in Japan and abroad. With a special focus on the distribution of sandstone layers for CO2 injection and mudstone layers for capping, INPEX has evaluated the injection potential of sites based on the spatiotemporal distribution of the respective rocks, with a thorough understanding of geology and geological history.

The criteria used for the site selection procedure for CCS includes the feasibility of CO2 injection as well as the safety aspects, e.g., no leakage to the surface after injection. As a company responsible for producing fossil fuels, which is a major source of CO2 emissions, INPEX aims to improve its CCS technologies and to contribute toward mitigating global warming.

DAS Technology Development

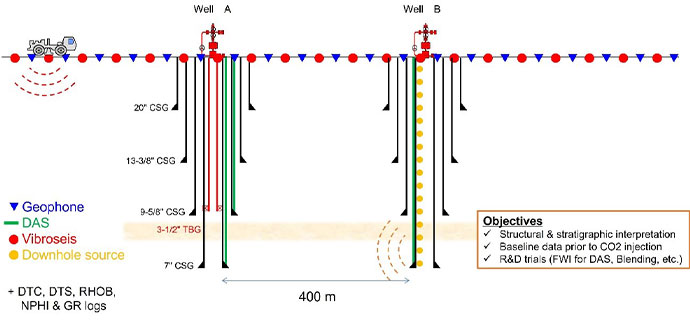

Distributed acoustic sensing (DAS) has garnered considerable attention as a promising technology that can reduce costs for seismic monitoring and acquisition, because it measures seismic waves using optical fibres embedded in wells and can be used as alternatives to seismometers.

DAS is an application of distributed fibre-optic sensing (DFOS) technology in which the optical fibres themselves are used as sensors for observing physical phenomena. In the petroleum industry, DFOS has been focused upon because these technologies can be potentially applied to drilling operations, subsurface structure evaluation, oil production, and pressure monitoring.

Specifically, as optical fibres are permanently installed in wells, the installation of receivers and survey lines during each instance of seismic survey is not required for DAS. Moreover, DAS is advantageous as it enables long-term usage of monitoring equipment over 10 years or more.

Since 2016, INPEX has developed technologies for conducting seismic surveys and subsurface monitoring with DAS to evaluate and verify CCS as well as maximize crude oil recovery by injecting carbon dioxide into the subsurface. In 2017, we conducted a vertical seismic profile (VSP) survey using optical fibres installed inside a coiled tube, which was the first such application in the world (Kobayashi et al., 2018). Furthermore, we developed technologies to process the recorded data (Kobayashi et al., 2019).

Currently, we are collaborating with domestic and foreign universities and research institutes in technical development to improve the accuracy of data acquisition in cross-well seismic survey and VSP survey using DAS.

References

Kobayashi, Y., Naruse, R. and Xue, Z. (2018) "On the feasibility of the monitoring of earthquake event utilizing an optical fiber deployed inside a well - an example of an earthquake event detected by passive DAS recording in a deep well in Japan -," BUTSURI-TANSA(Geophysical Exploration), 71, pp. 56–70.

Kobayashi, Y., Uematsu, Y., Mochiji, S. and Xue, Z., 2019. A field experiment of walkaway distributed acoustic sensing vertical seismic profile in a deep and deviated onshore well in Japan using a fibre optic cable deployed inside coiled tubing.