INPEX Chairman Naoki Kuroda

Australian Prime Minister Julia Gillard

Northern Territory Chief Minister Paul Henderson

TOTAL E&P Australia Managing Director Mike Sangster

May 18, 2012

Australian Prime Minister, the Hon. Julia Gillard, MP, officially launched construction of the Ichthys LNG Project at a ground breaking ceremony at Blaydin Point in Darwin, Northern Territory today.

At the invitation of INPEX CORPORATION Chairman Naoki Kuroda, the Prime Minister joined Northern Territory Chief Minister, the Hon. MLA Paul Henderson, MLA, and Total E&P Australia Managing Director Mike Sangster to signal the commencement of site works for Australia's newest LNG project.

The Hon. Adam Giles, the Chief Minister of The Northern Territory (second from right) and INPEX participants

September 18, 2013

The INPEX-operated Ichthys LNG Project (the Project) today officially opened the doors of its Accommodation Village at Howard Springs, Darwin. Named Manigurr-ma Village after the Larrakia name for the Stringybark tree, it will be home for up to 3,500 workers when it is complete in mid-2014. About 1,000 of the Project's construction workforce will move in to the village over the next few months.

FPSO Steel Cutting Ceremony

June 19, 2013

The INPEX-operated Ichthys LNG Project cut first steel yesterday for the hull of its Floating Production, Storage and Offloading (FPSO) facility in Okpo, Korea. With fabrication of the hull underway, work on all of the Ichthys LNG Project's major offshore facilities has commenced.

Ribbon Cutting at CPF Steel Cutting Ceremony

January 25, 2013

The INPEX-operated Ichthys LNG Project is on track to achieving first gas by the end of 2016 with the first steel cutting by Samsung Heavy Industries for what will be the world's largest semi-submersible platform.

The 150 metre by 110 metre large central processing facility (CPF) will displace 140,000 tonnes and will have a peak gas export rate of 1,657 MMscfd, making it the largest of its kind.

Christmas Tree

November 25, 2014

The INPEX-operated Ichthys LNG Project’s first christmas tree systems have arrived in Australia.The tree systems left the subsea manufacturing facility at Bridge of Don in Aberdeen, Scotland on 3 October and arrived safely at GE’s Jandakot facility in Western Australia on Sunday 16 November 2014.The delivered christmas tree systems weigh more than 100 tonnes each with fittings and associated structures, featuring the latest technology to meet specific requirements of the Ichthys LNG Project.

RSS tower

November 5, 2014

The INPEX-operated Ichthys LNG Project today successfully installed its Riser Support Structure (RSS) tower at the Ichthys Gas-condensate Field. The safe installation of the 6,500 ton structure by the deepwater construction vessel Aegir marks the beginning of the Project’s major installation campaign in the Browse Basin, offshore Western Australia.The completed RSS will be a physical, fixed support for flexible risers and dynamic umbilicals that connect subsea gathering systems to the Project’s semi-submersible central processing facility (CPF), currently under construction in Korea.

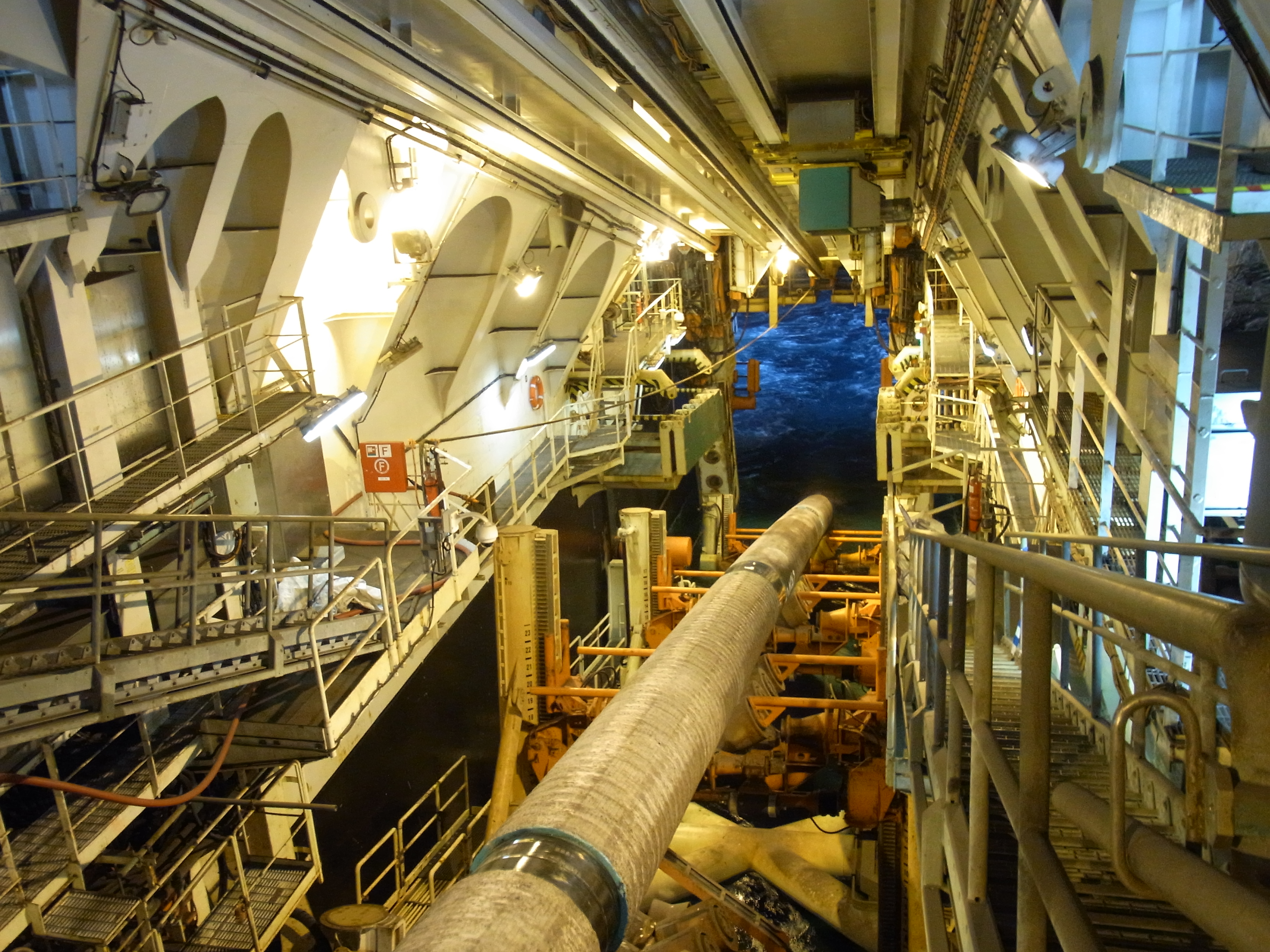

FPSO lower turret

November 4, 2014

The INPEX-operated Ichthys LNG Project today took a major step toward completion of the floating production, storage and offloading (FPSO) facility when the lower turret began its integration with the FPSO facility.The unique 4,200 ton, 31 meter-tall structure was safely inserted into the hull of the FPSO, which is currently under construction at Daewoo Shipbuilding and Marine Engineering (DSME), in Okpo, South Korea.Three components make up the overall FPSO turret: the lower turret, the manifold and the gantry frame. When completed, the full turret will measure 85 meters in height and weigh 8,700 tons, making it one of the largest in the world.

Ichthys LNG Project Completes Manigurr-ma Village

July 29, 2014

The INPEX-operated Ichthys LNG Project today announced the completion of its Accommodation Village at Howard Springs near Darwin in the Northern Territory.Manigurr-ma Village will provide a home for up to 3,500 Project personnel during peak construction.The 67 hectare village includes a 50-seat cinema, swimming pool, library, gym, running track, music room, basketball, beach volleyball and tennis courts, internet room and more. A twenty-four hour medical centre alleviates pressure on public health services and cuts unnecessary emergency call-outs.At full operation the village will employ about 200 management and maintenance staff.

Module unloading at MOF at Bladin Point, Darwin

July 1, 2014

INPEX-operated Ichthys LNG Project is preparing for the next phase of its onshore construction effort, following the unloading of its first large pre-fabricated modules on June 29th 2014. The modules will be used to construct the Project’s LNG processing facilities at Bladin Point near Darwin, Australia. The Ichthys LNG Project’s pre-fabricated modules are being built at four yards in China, the Philippines and Thailand. Over the next 18 months, about 60 module shipments are scheduled to arrive in Darwin and more than 200 modules will be loaded.

Deep water installation vessel Castorone

June 30, 2014

INPEX-operated Ichthys LNG Project commenced gas export pipeline (GEP) installation works on June 28th 2014, following the earlier arrival of the Saipem-operated, semi-submersible pipelay barge SEMAC-1 in the Northern Territory. The Project's 889 kilometre GEP will connect the onshore processing facilities near Darwin to the Ichthys gas-condensate field in the Browse Basin, offshore Western Australia.The SEMAC-1 will conduct the 164 kilometre shallow water pipelay installation which will take about 80 days. Once completed, the SEMAC-1 will transfer work to Saipem’s deep water installation vessel, Castorone, which will lay the remaining 718 kilometres of pipe to the Ichthys gas-condensate field.

Ichthys LNG Project

June 25, 2014

The INPEX-operated Ichthys LNG Project has celebrated its most significant construction milestone to date after officially marking 50 per cent completion. Ichthys includes an offshore project with subsea facilities and two large floating platforms (central processing facility and floating production storage and offloading facility); an onshore project featuring a 8.4 million tonne per annum LNG plant in Darwin; and an 889 km 42-inch gas transmission pipeline. This time milestone means that half of the overall Project scope has been completed.

Drilling Rig「ENSCO 5006」

April 30, 2014

The INPEX-operated Ichthys LNG Project has celebrated the arrival of its development drilling rig in Singapore, where it will undergo major upgrades before it is mobilised to the Ichthys gas-condensate field for the Project’s drilling campaign. Following completion of the upgrades in the shipyard, the rig will be towed to the Ichthys gas-condensate field to begin the production drilling and completion activities during the last quarter of 2014.

The First CPF Hull Block

April 3, 2014

The first dry dock hull block erection was celebrated on 2 April 2014, with a ribbon cutting ceremony in the Samsung Heavy Industries shipyard in Geoje, South Korea, where the CPF is being constructed.The CPF is a very large floating facility that gathers natural gas and condensate from the Ichthys Field's subsea wells. Gas will undergo initial processing on the CPF, which will be permanently moored at the field, to extract condensate and water and remove impurities in order to make the gas suitable for transmission.With topside dimensions of 150 metres by 110 metres, the CPF will be the world’s largest semi-submersible platform. After the construction completion in 2015, it will be towed around 6,000 kilometres to the Ichthys Field in the Browse Basin, offshore Western Australia.

FPSO Keel Laying

February 20, 2014

The INPEX-operated Ichthys LNG Project has celebrated a key milestone for its Floating Production, Storage and Offloading (FPSO) facility.

The first block of the keel was placed during a ceremony in the Daewoo Shipbuilding & Marine Engineering (DSME) shipyard in Okpo, South Korea, where the FPSO is being constructed.

Pipelay of gas export pipeline

November 05 2015

On November 5, the INPEX-operated Ichthys LNG Project safely completed the offshore pipelay for its 890-kilometer, 42-inch diameter gas export pipeline that began in June 2014.

As a key component supporting the Project, the 890-kilometer pipeline will deliver gas from the Project’s offshore facilities in Western Australia’s Ichthys Gas-condensate Field to the onshore facilities at Bladin Point near Darwin for final processing before export.

CPF float off

September 24 2015

The INPEX-operated Ichthys LNG Project safely launched its central processing facility (CPF) on September 19, 2015 from the offshore floating dock at the Samsung Heavy Industries shipyard in Geoje, South Korea, where it is being constructed.

This milestone is a clear demonstration that the Ichthys LNG Project is making good progress in an excellent spirit of cooperation with its Korean contractors.

Once completed, the CPF, which the Project began constructing in January 2013, will be towed 5,600 kilometers to the Ichthys Field in the Browse Basin, offshore Western Australia, where it will be permanently moored for the life of the Project ? more than 40 years.

First production manifold prepared for deployment

June 23 2015

The INPEX-operated Ichthys LNG Project has safely landed the first of five production manifolds on the seabed in the Ichthys Gas-condensate Field.

The 435-ton manifold was lowered in June 2015. The four remaining manifolds will be installed throughout 2015.

When operational the five manifolds will collect production from the subsea wellheads and distribute it to the Project’s central processing facility via production flowlines and flexible risers.

A subsea mooring pile prepared for deployment

May 8, 2015

The INPEX-operated Ichthys LNG Project has begun the installation of subsea mooring piles in the Ichthys gas-condensate field to prepare for the arrival of the CPF and FPSO in 2016. The facilities, currently under construction in South Korea, will be secured to a total of 49 mooring piles with 40,000 tons of chain.

Each pile is about 66m long and weighs more than 450 tons. The mooring piles will be installed by the deepwater construction vessel DCV Aegir starting in May 2015.

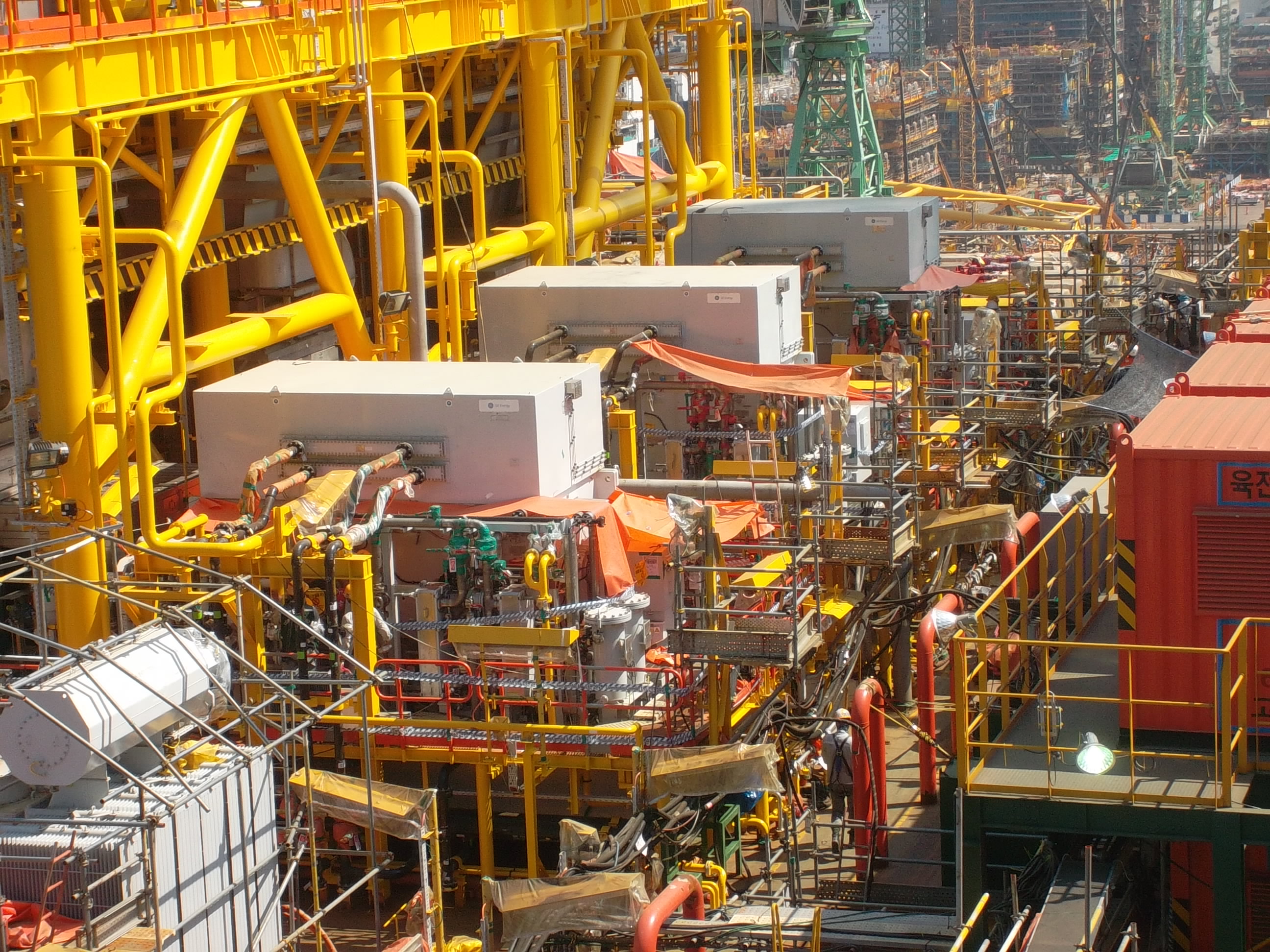

The first CPF topside module is lifted

April 23, 2015

The INPEX-operated Ichthys LNG Project has begun the topside integration phase for the central processing facility (CPF) and the floating production, storage and offloading (FPSO) facility.

This phase involves the hull and topside for each facility coming together as single, connected structures, and marks a major step towards the completion of the two world-class, semi-submersible facilities.

The CPF and FPSO topsides, which weigh a combined 120,000 tons, include all of the equipment required to safely and efficiently process, store and offload gas and condensate offshore, as well as provide living quarters for the workforce on both facilities.

Large pre-fabricated module

April 13, 2015

The arrival of six large pre-fabricated modules weighing about 7,500 tons combined in two shipments from STP&I and AG&P rounded out first deliveries from all four yards fabricating equipment for the Ichthys LNG Project’s onshore liquefaction plant.

Nearly 60 large pre-fabricated modules have now been delivered safely to the site, with many already installed.

The pre-fabricated modules, which are up to around 90 meters in length, are key components of the project’s LNG processing facilities, and are being built at four fabrication yards in China, the Philippines and Thailand.

Deepwater pipelay

February 9, 2015

The INPEX-operated Ichthys LNG Project has today started the deepwater pipelay for its 889 kilometer-long gas export pipeline (GEP). Saipem’s deepwater installation vessel Castorone will lay the remaining 718 kilometer offshore section of the 42-inch diameter GEP following the successful completion in November 2014 of the 164 kilometer shallow water section by the SEMAC-1. Deepwater pipelay is scheduled for completion in late 2015.

ENSCO-5006

February 4, 2015

The INPEX-operated Ichthys LNG Project commenced drilling at the Ichthys gas-condensate field, about 200km off the Western Australian coast.

The first development well was spudded on February 3 by the Project’s development drilling rig ENSCO-5006, which recently arrived at the field after undergoing major upgrades in Singapore. The ENSCO-5006 will soon be joined by an additional rig, which will also take part in the drilling campaign.

The campaign will target the Brewster reservoir with 20 production wells. The wells will be drilled into reservoirs about 4,000 to 4,500 meters beneath the seabed.

Pipelay of gas export pipeline at Bladin Point, near Darwin

November 09, 2016

The offshore and onshore sections of the INPEX-led Ichthys LNG Project’s 890 kilometer gas export pipeline were safely welded together in Darwin today.

Joining the two pipeline sections?882 kilometers offshore and eight kilometers onshore?means the pipeline is now ready to deliver gas from the offshore Ichthys Gas-condensate Field to the Project’s onshore facilities at Bladin Point near Darwin for processing.

Main power generators switched on for the CPF

September 09, 2016

The INPEX-led Ichthys LNG Project has reached a key milestone with both the Central Processing Facility (CPF) and Floating Production, Storage and Offloading (FPSO) facility safely starting up their main power generators in the South Korean shipyards where they are being constructed.

On September 8, the CPF's three generators run by 25 megawatt dual-fuel gas turbines energized the facility's distribution network, while the FPSO's main turbo-generators were started up on July 28.

Starting up the main generators of the FPSO and CPF allows the commissioning to further progress by providing the required power for both facilities.

Final three modules arrive in Darwin to complete construction of the Project's onshore processing facilities

September 06, 2016

The INPEX-operated Ichthys LNG Project reached a significant milestone today with the arrival of the final three modules required to complete construction of the Project’s onshore processing facilities.

The modules will next be connected with other modules to complete the two LNG processing trains that will liquefy gas transported to Darwin via the 890-kilometre Gas Export Pipeline from the Ichthys Gas-condensate Field.

In total, 230 modules have arrived from the Project’s four fabrication yards in Thailand, China and the Philippines, in a process that began in June 2014.

The final FPSO topside module being lifted at the shipyard in Okpo, South Korea

May 16, 2016

The INPEX-operated LNG Ichthys Project achieved a major step forward when the last topside lift on the floating production, storage and offloading (FPSO) was safely completed in South Korea on 12 May 2016.

The lift marks an important milestone in the integration phase for the Project’s offshore facilities and progression towards pre-commissioning and commissioning activities for the FPSO.

A total of about 46,000 tons of topside modules, piperacks and equipment packages have been safely lifted onto the hull of the FPSO.

Sea-fastening of CPF mooring chains on transport barge in Batam

May 11, 2016

The INPEX-operated Ichthys LNG Project recently reached a significant milestone with the offshore installation of a 77 kilometer chain and cable mooring system in the Ichthys Gas-condensate Field, located in the Browse Basin, off the northern coast of Western Australia. The system will anchor the FPSO and the CPF facility to the seabed for at least 40 years of continuous operation.

Supplying more than 40,000 tons of chain to the Ichthys Project represented nearly 18 months of worldwide production of large-scale chains, with each chain link weighing more than 700 kilograms.

Installation of rigid subsea flowlines

February 23, 2016

In February 2016, the INPEX-operated LNG Ichthys Project announced a key milestone when it successfully completed the installation of 140 kilometers of rigid subsea flowlines.

The infield flowlines were installed in a water depth of up to 275 meters to carry reservoir fluids from 20 subsea wells to the Project’s central processing facility.

All flowlines were installed with in-line structures, weighing up to 220 tons, requiring a total of more than 11,000 onshore and offshore welds to be executed.

In addition to the infield flowlines, the Ichthys LNG Project offshore installation campaign has completed installation of 49 foundation piles, five production manifolds and a 6,500 ton riser support structure.

The Ichthys LNG Project has successfully completed concrete roof pours for both of its two LNG tanks

February 12, 2016

On February 10, 2016, the INPEX-operated Ichthys LNG Project completed construction of the reinforced concrete roofs for both of its onshore liquefied natural gas storage tanks.

The final concrete pour for the roof of the second LNG tank was recently undertaken at the Project's onshore construction site at Bladin Point near Darwin, Australia. Each of the cryogenic tanks stands nearly 47 meters tall and will have a volume of 165,000 cubic meters, which is the equivalent of 160 Olympic swimming pools.

A module delivered from Thailand’s CUEL yard to Darwin

January 29, 2016

The INPEX-operated Ichthys LNG Project marked a major milestone this week with the last seven modules manufactured at the CUEL fabrication yard in Thailand arriving at the Project’s onshore gas liquefaction plant construction site in Darwin, Australia.

More than 151 modules?equating to a combined weight of 38,462 tons?were supplied from CUEL, providing key components of the Project’s state-of-the-art onshore LNG processing facilities.

Two of four fabrication yards have now completed module shipments. Modules from China finished in July 2015, while yards in Thailand and the Philippines continue to manufacture modules.

Ichthys LNG Project combined cycle power plant (CCPP)

November 10, 2017

The INPEX-operated Ichthys LNG Project safely and successfully initiated the start-up of its gas turbine generators at its combined cycle power plant (CCPP) that will supply all the electricity requirements for the project’s onshore gas liquefaction plant near Darwin, Australia.

The CCPP will be powered by natural gas from the Ichthys Field and use a mix of five gas and three steam turbine generators to produce up to 50% more electricity(1) from the same amount of fuel compared with a traditional simple-cycle power plant. Ultimately, the CCPP will deliver up to 490 megawatts of electricity.

Combined cycle technology will also significantly reduce greenhouse gas and other air emissions from the project.

(1) The waste heat from the gas turbines will be utilized to create steam for the steam turbine system, which generates extra power.

Ichthys Venturer undergoing mooring operations

August 25, 2017

The INPEX-operated Ichthys LNG Project’s Floating Production, Storage and Offloading (FPSO) facility (Ichthys Venturer) has been safely moored in the 250-metre deep waters of the Ichthys Field, located about 200 kilometers off the Western Australian coast.

The complex operation involved connecting 21 pre-installed mooring chains, weighing more than 15,000 tons, from the seabed to the FPSO.

FPSO"Ichthys Venturer" arrives at the Ichthys Field

August 14, 2017

The INPEX-led Ichthys LNG Project celebrated the safe arrival of the Floating Production Storage and Offloading (FPSO) facility "Ichthys Venturer" today at the Ichthys Field located about 200 kilometers off the Western Australian coast, following a 26-day tow.

After Ichthys Venturer is safely moored, hook up and commissioning will begin.

FPSO (Ichthys Venturer) sail away

July 19, 2017

The Ichthys Venturer, the INPEX-operated Ichthys LNG Project’s Floating Production Storage and Offloading facility (FPSO), sailed away from waters near its construction site in Okpo, South Korea en route to the Ichthys Field offshore Western Australia, following the completion of shipyard commissioning and preparation work.

The Ichthys Venturer will be towed to the Ichthys Field over a period of approximately one month, after which it is scheduled to undergo hook-up. The facility will undertake the role of temporarily storing condensate separated and produced by the Central Processing Facility (CPF) located offshore approximately 3.5 kilometers away and offloading the condensate to buyers’ tankers over 40 years of continuous operation.

Ichthys Explorer undergoing mooring operations

June 22, 2017

The INPEX-operated Ichthys LNG Project’s Central Processing Facility (CPF) has been safely moored in the 250-metre deep waters of the Ichthys Field, located about 200 kilometers off the Western Australian coast.

The complex operation involved connecting 28 pre-installed mooring chains, weighing more than 25,000 tons, from the seabed to the CPF.

Aerial view of the Ichthys LNG Project's new operations complex at Bladin Point, Darwin, Australia

June 14, 2017

A state-of-the-art operations complex for the INPEX-operated Ichthys LNG Project is now in use as the onshore processing plant site prepares for transition from construction to operations.

Situated nearly two kilometers from the LNG processing plant at Bladin Point, Darwin and covering approximately 23 hectares, the complex of 20 permanent buildings makes up a sophisticated control and support hub for the onshore processing of gas received from the Ichthys Gas-condensate Field.

The complex includes a central control building, laboratory, administration offices, mechanical, instrument, electrical and communications workshops and several warehouses to safely support the operation of the Ichthys LNG Project's onshore plant.

Ichthys Explorer, the world’s largest central processing facility

May 29, 2017

The INPEX-led Ichthys LNG Project celebrated the safe arrival of the central processing facility (CPF) today at the Ichthys Field located about 200 kilometers off the Western Australian coast, following a 34-day tow.

After Ichthys Explorer is safely moored, hook up and commissioning will begin.

CPF (Ichthys Explorer) sail away

April 28, 2017

The Ichthys Explorer, the INPEX-operated Ichthys LNG Project’s central processing facility (CPF), sailed away from its construction site in Geoje, South Korea en route to the Ichthys Field offshore Western Australia, following the completion of shipyard commissioning and preparation work.

The Ichthys Explorer will be towed to the Ichthys Field over a period of approximately one and a half months, after which it is scheduled to undergo hook-up. The facility will then separate and process the produce lifted from subsea production wells into gases and liquids over 40 years of continuous operation.

Naming ceremony of the “Ichthys Venturer”

February 17, 2017

The INPEX-operated LNG Ichthys Project held a double-celebration in South Korean shipyards on February 17, 2017 with the naming of both offshore facilities belonging to the Project, following the completion of construction of these facilities.

At Daewoo Shipbuilding and Marine Engineering (DSME) shipyard this morning, former Chief Minister of the Northern Territory of Australia the Hon. Clare Martin officially named the Project’s floating production, storage and offloading (FPSO) facility “Ichthys Venturer.”

In the afternoon at Samsung Heavy Industries (SHI) shipyard, the Hon. Julie Bishop MP, Australian Minister for Foreign Affairs officially named the Project’s central processing facility (CPF) “Ichthys Explorer.”

Spool lift in progress

January 13, 2017

The INPEX-operated LNG Ichthys Project reached a key milestone with the successful completion of the installation of the complex network of subsea infrastructure and equipment to safely and efficiently extract natural gas and condensate from the Ichthys Gas-condensate Field.

Included in the extensive subsea gathering system is a riser support structure, manifolds, flowlines, umbilicals and flying leads, production and MEG spools, subsea distribution units and a subsea distribution hub.

A remaining umbilical will be installed during the CPF and FPSO hook-up campaign.

Event commemorating the commencement of Project operations

From left: INPEX Chairman Toshiaki Kitamura; the Hon Michael Gunner, Chief Minister of the Northern Territory; the Hon Scott Morrison MP, Prime Minister of Australia; HE Shinzo Abe, Prime Minister of Japan.

November 19, 2018

The INPEX-operated Ichthys LNG Project hosted an event in Darwin in the Northern Territory of Australia on November 16, 2018 commemorating the commencement of Project operations. The event was attended by HE Shinzo Abe, Prime Minister of Japan, the Hon Scott Morrison MP, Prime Minister of Australia, Senator the Hon Matthew Canavan, Australian Minister for Resources and Northern Australia, Hiroshige Seko, Japanese Minister of Economy, Trade and Industry (METI), the Hon Michael Gunner, Chief Minister of the Northern Territory, representatives of the governments of Japan and Australia, Ichthys LNG buyers, financial institutions involved in the financing of the Project, members of the local communities and other Project stakeholders.

Also on November 16, a plaque unveiling ceremony commemorating the startup of the Project's onshore gas liquefaction plant was held at the onshore plant site in the presence of Senator the Hon Simon Birmingham, Australian Minister for Trade, Tourism and Investment, Senator the Hon Matthew Canavan, Australian Minister for Resources and Northern Australia and Hiroshige Seko, Japanese Minister of Economy, Trade and Industry (METI), among others.

The Project's first LPG shipment undertaken by the LPG carrier "Hellas Gladiator"

November 16, 2018

The Ichthys LNG Project commenced shipment of liquefied petroleum gas (LPG) as the first LPG cargo departed the onshore gas liquefaction plant in Darwin in the Northern Territory of Australia. The cargo is destined to an Asian buyer.

Through the Project, INPEX will continue to respond to the energy demand in Japan, Asia and the rest of the world.

The Project's first LNG shipment undertaken by the LNG carrier "Pacific Breeze"

October 23, 2018

The Ichthys LNG Project commenced shipment of liquefied natural gas (LNG) as the first LNG cargo departed the onshore gas liquefaction plant in Darwin in the Northern Territory of Australia. The cargo is now heading to the INPEX-operated Naoetsu LNG Terminal in Niigata Prefecture, Japan.

INPEX will further contribute to the stable supply of energy to Japan through the Project and continue to respond to the energy demand in Asia and the rest of the world.

Shipping of condensate from the Floating Production, Storage and Offloading (FPSO) facility "Ichthys Venturer" and the Central Processing Facility "Ichthys Explorer" in the background (far right)

October 01, 2018

The INPEX-operated Ichthys LNG Project recently commenced shipment of condensate (ultra-light crude oil), one of the Project's products, from the Floating Production, Storage and Offloading (FPSO) facility "Ichthys Venturer."

The first shipment of condensate is destined for the Asian market. INPEX is poised to continue responding to the energy demand in Japan, Asia and the rest of the world.

Ichthys Gas-condensate Field

July 30, 2018

The INPEX-operated Ichthys LNG Project has commenced production of gas from the wellhead.

Production of the condensate, LPG and LNG will follow in sequence.

The Project expects to proceed with the shipment of cargoes towards the end of the first half of the current fiscal year.

Ichthys Explorer

May 31, 2018

The INPEX-operated Ichthys LNG Project has completed the commissioning of its Central Processing Facility (Ichthys Explorer) required for production start-up. This milestone marks the completion of the necessary commissioning of all key onshore and offshore facilities for production start-up.

The Project is scheduled to commence production of gas from the wellhead upon conducting final safety verifications, and will thereafter proceed with the shipment of cargo by the end of the first half of the current fiscal year.

LNG carrier “Oceanic Breeze” arrives at Naoetsu LNG Terminal from the Ichthys LNG Project

2019/02/12

The LNG Tanker Oceanic Breeze recently called for the first time at INPEX’s Naoetsu LNG Terminal located in Joetsu City, Niigata Prefecture, Japan, delivering a cargo of liquefied natural gas (LNG) from the Ichthys LNG Project in Australia.

Oceanic Breeze is 30% owned by an INPEX subsidiary, and designated to transport the 0.9 million tons per year of Ichthys LNG entitled to INPEX.